2.5 Ton Electric Lift Truck

Streamlined Design: With its family-style exterior design, this forklift inherits a effortless however nice appear characterised with the useful resource of flowing lines. It exudes a natural and dynamic sensation, offering a smooth appearance.

Temperature Resilience: The lithium battery has handed thru rigorous checking out for sturdiness in extreme temperature conditions. It continues terrific ordinary overall performance in temperatures ranging from -40°C to 60°C, making the car adaptable to a sizable range of temperature-related working conditions.

Impressive Performance: Featuring a high-power stress motor and oil pump motor, this vehicle achieves exquisite driving pace and impervious lifting performance. It guarantees surroundings pleasant power output and robust performance, succesful of competing with internal combustion forklifts of related tonnage and surpassing lead-acid battery forklifts via a exceptional margin.

Product Description:

Allow us to introduce the BYD ECB25, an electric powered powered truck succesful of dealing with a most workload of 2.5 tons. This BYD forklift boasts an ergonomic design that enhances operator comfort and productiveness during work shifts. Additionally, the terrific speed of its charging times, coupled with the utilization of a single battery that consists of present day BYD lithium iron phosphate technology, approves firms to attain giant price cut price prices.

Product Parameter:

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | ECB25 | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Seat | |||

1.5 | Rated capacity | Q | kg | 2500 | |

1.6 | Load center | c | mm | 500 | |

1.8 | Load distance, center of drive axle to fork | x | mm | 425 | |

1.9 | Wheelbase | y | mm | 1505 | |

weight | 2.1 | Service weight | kg | 4200 | |

2.2 | Axle load, with load, front/rear | kg | 5811/889 | ||

2.3 | Axle load, without load, front/rear | kg | 1775/2425 | ||

Wheels, Chassis

| 3.1 | Tyres | SE | ||

3.2 | Tyre size, front | 21×8-9 | |||

3.3 | Tyre size, rear | 18×7-8 | |||

3.5 | Wheels, number front rear (x=driven wheels) | 2×/2 | |||

3.6 | Track width, front | b10 | mm | 1000 | |

3.7 | Track width, rear | b11 | mm | 955 | |

Basic dimensions

| 4.1 | Tilt of mast/fork carriage forward/backward | a/b | deg | 5/8 |

4.2 | Height, mast lowered | h1 | mm | 2030 | |

4.3 | Free lift | h2 | mm | 140 | |

4.4 | Lift height | h3 | mm | 3000 | |

4.5 | Height, mast extended | h4 | mm | 4040 | |

4.7 | Height of overhead guard | h6 | mm | 2195 | |

4.8 | Seat height | h7 | mm | 1100 | |

4.12 | Coupling height | h10 | mm | 333 | |

4.19 | Overall length | l1 | mm | 3375 | |

4.20 | Length to face of forks | l2 | mm | 2305 | |

4.21 | Overall width | b1 | mm | 1195 | |

4.22 | Fork dimensions | s/e/l | mm | 40/100/1070 | |

4.23 | Fork carriage ISO 2328,class/type A,B | 2A | |||

4.24 | Fork carriage width | b3 | mm | 1085 | |

4.31 | Ground clearance, with load, below mast | m1 | mm | 95 | |

4.32 | Ground clearance, center of wheelbase | m2 | mm | 105 | |

4.33 | Aisle width of pallets 1000×1200 crossways | Ast | mm | 3646 | |

4.34 | Aisle width of pallets 800×1200 lengthways | Ast | mm | 3845 | |

4.35 | Turning radius | Wa | mm | 2020 | |

Performance Data | 5.1 | Travel speed, with/without load | Km/h | 20/20 | |

5.2 | Lift speed, with/without load | mm/s | 420/450 | ||

5.3 | Lowering speed, with/without load | mm/s | 500/400 | ||

5.6 | Max. drawbar pull, with/without load | KN | 12.7/9.5 | ||

5.8 | Max. gradeability, with/without load | % | 20/20 | ||

5.10 | Service brake | Mech./Hydr. | |||

Motors | 6.1 | Drive motor rating S2 60 min. | kW | 8×2 | |

6.2 | Lift motor rating at S3 15% | kW | 20.7 | ||

6.4 | Battery voltage, nominal capacity K5 | V/Ah | 80/270 | ||

6.5 | Battery weight | kg | 350 | ||

Others

| 8.1 | Type of drive control | AC | ||

8.2 | Operating pressure for attachments | Bar | 168 | ||

8.4 | Sound level at the driver’s ear | dB(A) | ≤75 | ||

8.5 | Towing coupling, type | PIN |

Mast specifications:

h3 Lifting Height(mm) h2 Full Free Lift Height(mm) h1 Height, Mast Full Lowered(mm) h4 Height, Mast Full Extended(mm)(Load Backrest 1000mm) α Tilt Forward β Tilt Backward

Mast Specifications(mm) | h3 | h2 | h1 | h4 | α | β | Residual Capacity(kg) | |

ECB25@500MM | ECB25@600MM | |||||||

2-stage standard Mast | 3000 | 140 | 2030 | 3990 | 5° | 8° | 2500 | 2450 |

3300 | 140 | 2180 | 4290 | 5° | 8° | 2500 | 2380 | |

3500 | 140 | 2280 | 4490 | 5° | 8° | 2500 | 2340 | |

4000 | 140 | 2580 | 4990 | 5° | 8° | 2380 | 2210 | |

4500 | 140 | 2830 | 5490 | 5° | 5° | 2230 | 2080 | |

5000 | 140 | 3130 | 5990 | 5° | 5° | 2110 | 1980 | |

2-stage FFL Mast | 3000 | 1070 | 2060 | 3990 | 5° | 8° | 2500 | 2450 |

3300 | 1220 | 2210 | 4290 | 5° | 8° | 2500 | 2380 | |

3500 | 1320 | 2310 | 4490 | 5° | 8° | 2500 | 2340 | |

4000 | 1570 | 2560 | 4990 | 5° | 8° | 2380 | 2210 | |

3-stage FFL Mast(Dual full free lift mast) | 4000 | 960 | 1950 | 4990 | 5° | 5° | 2380 | 2210 |

4500 | 1120 | 2110 | 5490 | 5° | 5° | 2230 | 2080 | |

4800 | 1120 | 2210 | 5790 | 5° | 5° | 2160 | 2020 | |

5000 | 1285 | 2275 | 5990 | 5° | 5° | 2110 | 1980 | |

5500 | 1470 | 2460 | 6490 | 5° | 5° | 2000 | 1880 | |

6000 | 1680 | 2670 | 6990 | 5° | 5° | 1800 | 1780 | |

6500 | 1840 | 2830 | 7490 | 5° | 5° | 1700 | 1600 | |

3-stage FFL Mast(Single full free lift mast) | 4000 | 935 | 1925 | 4990 | 5° | 5° | 2380 | 2210 |

4500 | 1095 | 2085 | 5490 | 5° | 5° | 2230 | 2080 | |

4800 | 1195 | 2185 | 5790 | 5° | 5° | 2160 | 2020 | |

5000 | 1255 | 2245 | 5990 | 5° | 5° | 2110 | 1980 | |

5500 | 1455 | 2445 | 6490 | 5° | 5° | 2000 | 1880 | |

6000 | 1665 | 2655 | 6990 | 5° | 5° | 1800 | 1780 | |

6500 | 1885 | 2815 | 7490 | 5° | 3° | 1700 | 1600 | |

7000 | 2045 | 3035 | 7990 | 3° | 3° | 1100 | 1100 | |

7500 | 2245 | 3235 | 8490 | 3° | 3° | 700 | 700 | |

Classification:

Multi-function armrest with fingertip control 2. Seat with full suspension 3. Mast with full free double lifting cylinders 4. Curve speed adjustment to decorate steadiness and minimize chance of overturning 5. Brake useful resource when it detects that the operator is releasing the brake on a ramp or slope 6. Limitation of the the the front tilt mindset to restriction the hazard of load drop when the load exceeds 10% of the set weight, the engine stops working for safety’s sake 7. Multifunction TFT exhibit with scrolling speed, ultimate battery capacity, clock with working hours and collected hours, and three pace modes

Optional configuration:

Reverse voice warning 2. Reverse horn 3. Reverse camera 4. Reverse radar 5. Forklift camera 6. Orange seatbelt warning 7. Strobe light 8. Front blue light 9. Rear blue light 10. Work lights (rear) 11. Blue laser light 12. Panoramic rearview mirror 13. Fan 14. Fire extinguisher 15. Special key (single-point ignition switch) 16. Synchronized steering 17. Turning speed limit 18. Simple canopy 19. Semi-enclosed cabin (front windshield wiper + rain canopy) 20. Fully enclosed cabin 21. 200A charger 22. Inflatable tires, eco-friendly tires 23. Customized door frame 24. Customized cargo guard 25. Customized fork hands

Use:

Manufacturing, Paper Industry, Automotive Industry, Feed Industry, Household Appliance, Logistics, Food and Beverage

Product advantages:

Streamlined Design With its family-style exterior design, this forklift inherits a effortless however wonderful appear to be characterised thru flowing lines. It exudes a natural and dynamic sensation, imparting a smooth appearance.

2. Temperature Resilience The lithium battery has handed thru rigorous checking out for sturdiness in extreme temperature conditions. It continues exceptional common overall performance in temperatures ranging from -40°C to 60°C, making the vehicle adaptable to a enormous range of temperature-related working conditions.

3. Impressive Performance Featuring a high-power pressure motor and oil pump motor, this auto achieves high-quality the usage of tempo and tightly closed lifting performance. It offers you surroundings pleasant electrical energy output and sturdy performance, succesful of competing with internal combustion forklifts of same tonnage and surpassing lead-acid battery forklifts with the resource of a big margin.

4. Extended Warranty We adhere to stringent agency necessities for warranties, imparting a generous 5-year or 12,000-hour assurance for the battery. This dedication ensures actual peace of thinking for our valued customers.

5. Dependability and Trustworthiness The total automobile undergoes whole checking out for reliability, stability, safety, and comfort, guaranteeing that each vehicle reaches its peak operational condition. It is a testament to its reliability and stability, handing over assured quality.

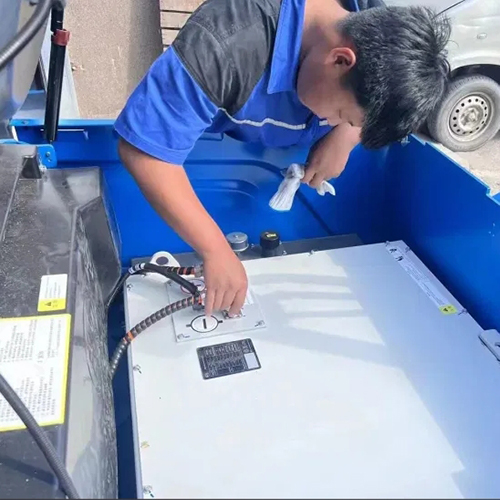

Product inspection:

BYD, a forklift manufacturer, continues stringent product evaluation and wonderful manipulate techniques at some stage in the manufacturing of forklifts to uphold extremely good and average overall performance standards. These inspections begin with:

Raw Material Assessment: Throughout the manufacturing process, BYD scrutinizes the raw resources employed. This consists of inspecting steel, digital components, lubricants, coatings, and more. These components want to adhere to special extremely good necessities and specifications.

Manufacturing Process Evaluation: During forklift manufacturing, BYD cautiously video show devices and assesses essential manufacturing tiers to make positive each and every thing meets format specifications. This consists of inspections of welding, mechanical processing, electrical connections, and distinctive indispensable aspects.

Performance Validation: Once the forklift is completely assembled, rigorous common overall performance tests are conducted. This encompasses assessments of engine power, suspension systems, brake systems, driver manipulate systems, and higher to confirm that the forklift meets predefined typical overall performance criteria.

Safety Verification: BYD forklifts undergo huge safety checking out to assurance compliance with relevant safety standards. This consists of tests such as collision tests, stability assessments, electrical safety examinations, and others.

Quality Control: BYD implements a entire super manipulate system encompassing inspection and attempting out procedures, meticulous record-keeping, employee training, and more. This computing device is designed to make certain steady product quality.

Final Inspection: Following the completion of forklift production, a whole closing inspection is conducted. This entails a thorough examination of the entire forklift to affirm proper component installation, absence of evident defects, and extraordinarily properly performance.

Product Certification: Forklifts that efficiently pass by all required inspections and tests might also moreover get maintain of extremely good product certifications as proof of compliance with global and regional excellent and protection standards.

Packaging and transportation:

Manufacturers and suppliers normally take accountability for the packaging and transportation of forklifts to make positive their impenetrable transport without any damage.

Packaging: Forklifts are generally enclosed in packaging until now than leaving the manufacturing unit to protect their seem to be and mechanical elements from manageable damage in the course of transit. This packaging often consists of the use of trees crates, foam padding, plastic film, and strapping materials to shield the forklifts from influences and collisions for the duration of transportation.

Inspection and Testing: Prior to departing the factory, producers commonly subject the forklifts to rigorous inspections and checking out to assurance their proper functioning and covered transportability. This consists of inspecting mechanical components, batteries, brake systems, and distinctive fundamental elements.

Shipping: Once the forklifts are effectively packaged and skip by way of inspection, they are equipped for shipment. Depending on factors such as distance, region, country, and patron requirements, forklifts can be transported to their holiday spot through a vary of means, such as avenue transportation, sea shipping, air freight, or extraordinary fabulous methods.

Documentation and Permits: Depending on the requirements of the Location or region, it can also moreover be fundamental to furnish relevant archives and approves to make positive that the forklifts can legally enter and be used in the specific area.

Company introduction:

Founded in 2009, BYD Forklift is a subsidiary of BYD Co., Ltd., placed in the Zhenjiang district of Shaoguan City. The entire funding for this undertaking portions to 515 million RMB, defending an expansive region of about 700,000 rectangular meters. The major middle of interest of this facility lies in the manufacturing of greater than a few series of BYD electric powered powered forklifts, encompassing electric powered powered counterbalance forklifts, electric powered powered warehouse forklifts, electric powered powered tow tractors, and more.

BYD Forklift boasts a entire forklift manufacturing line, comprising four machining and welding lines, one painting line, and three final assembly lines, culminating in an annual manufacturing plausible of 30,000 units. Additionally, the manufacturing unit is geared up with a dedicated checking out line and a whole great system, licensed below ISO9001, which ensures the gorgeous necessities of every and each forklift, thereby turning in incredible top notch and first-rate issuer to customers.

With the aspiration to set up itself as a primary worldwide organisation in electric powered powered forklifts, BYD Forklift adheres to the enchancment philosophy of "Pursuing excellence and continuous innovation." The business enterprise consistently enhances and updates its product range, catering to a wide spectrum of features spanning from warehousing and logistics to port and terminal logistics. Market growth efforts embody greater than a few industries, alongside with pharmaceuticals, food, cold chain processing, cosmetics, logistics, and more. BYD electric powered powered forklifts have garnered huge acclaim from domestic and world purchasers for their extraordinarily properly advantages in environmental sustainability and electrical energy efficiency, solidifying their characteristic as a globally relied on brand.

In alignment with market demands, BYD Forklift is at present placing up a whole electric powered powered forklift base in the Ningbo Industrial Park, the vicinity look up and development, production, sales, and after-sales service will be integrated. Upon completion, this mission will be a central hub in the Yangtze River Delta, serving East China and extending its gain nationwide and internationally. The deliberate funding for BYD Forklift's Ningbo manufacturing facility portions to 5 hundred million RMB and consists of a 60,000 rectangular meters facility encompassing methods such as automobile machining, welding, painting, assembly, and modification. The manufacturing facility will have the potential to produce 20,000 electric powered powered counterbalance forklifts and 30,000 warehouse forklifts annually.

Customer visit:

Prior to client visits, the earnings or buyer service companies commonly prepare appointments with customers, cautiously coordinating the timing, location, and agenda for the visit. This coordination is frequently carried out by way of talent such as mobile phone calls, emails, or exceptional verbal trade methods. The organizations moreover outline the special things to be addressed for the length of the meeting, encompassing product presentations, bother resolution, teaching sessions, business corporation negotiations, or contract signings, amongst exceptional matters. In preparation, BYD's consumer company companies usually gather pertinent archives and presentation components to share with customers, which can additionally embody product manuals, presentation slides, samples, and more.

Upon the conclusion of the visit, BYD's profits or customer issuer agencies usually record the content material fabric of the meeting, summarize the consequences of discussions, and outline plans for the subsequent steps. Additionally, they keep ongoing verbal alternate with consumers to make positive that their needs and requirements proceed to be addressed and met.

FAQ:

1. Q: Does BYD forklifts provide after-sales service?

A: Yes, BYD offers whole after-sales services, inclusive of maintenance, spare elements supply, training, and technical support, to make positive that customers' forklifts continue to be in most dependable condition.

2. Q: Does BYD forklifts furnish customization options?

A: Yes, BYD typically affords customization preferences to meet special patron requirements. You can get in contact with their profits crew to speak about the possibilities of customizing a forklift.

3. Question: Do BYD electric powered powered forklifts comply with international necessities and certifications?

Answer: Yes, BYD electric powered powered forklifts normally conform to global safety and fantastic necessities and attain relevant certifications. This consists of CE certification, ISO certification, and more, to make positive the legality and fantastic of the merchandise in world markets.

4. Question: Can BYD electric powered powered forklifts adapt to high-quality electrical energy standards?

Answer: Yes, BYD electric powered powered forklifts normally have multi-power compatibility and can adapt to exceptional countries' and regions' electricity necessities and voltages. This allows them to be used globally.

5. Question: Are BYD electric powered powered forklifts fantastic for indoor and backyard use?

Answer: Yes, BYD electric powered powered forklifts are splendid for every indoor and out of doorways use. Their graph typically consists of components that adapt to a range of working environments, such as indoor warehousing and backyard logistics operations.

6. Question: What is the fluctuate or battery existence of BYD electric powered forklifts?

Answer: The differ or battery existence of BYD electric powered powered forklifts depends upon on the specific model and battery capacity. BYD electric powered powered forklifts generally grant adjustable battery capacities to meet extra than a few utility needs. The fluctuate or battery existence is typically genuine in the product specifications.