BYD Stand-on Pallet Stacker S20

Easy Maintenance: Utilizing CAN-BUS science for handy fault prognosis and troubleshooting, with a multifunctional instrument panel showing battery level, hours of operation, fault maintenance, etc., for intuitive convenience.

Safe and Reliable: Equipped with security guardrails and shock-absorbing foot mats for higher driver protection. Also, points such as overload safety and whole-vehicle strength cutoff safety make sure worry-free operation.

Simple Operation: The multifunctional cope with presents limitless adjustment for a greater relaxed and tightly closed operation, whilst the electric powered electricity guidance device makes using simpler for the operator.

Versatility: Various mast specs are accessible to meet unique working situation requirements.

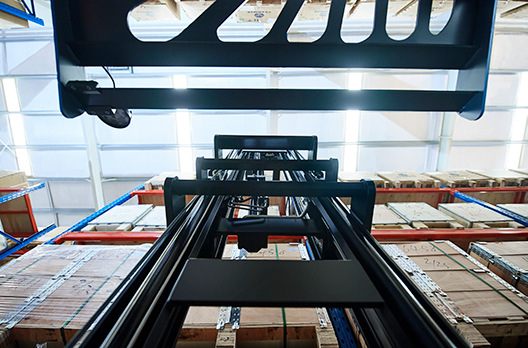

Product Description:

BYD S20 is a stand-on stacker with foldable facet bars and platform. This truck additionally has a rated ability of 2000 kg, with the carry heights up to 5400mm.

Product Parameter:

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | S20 | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Stand-on/Pedestrian | |||

1.5 | Load capacity | Q | kg | 2000 | |

1.6 | Load center | C | mm | 600 | |

weight | 2.1 | Service weight | kg | 1250 | |

Wheels | 3.1 | Wheel type | PU | ||

Dimensions | 4.3 | Height of tiller lift | h14 | mm | 1550 |

4.4 | Lift height | h3 | mm | 3000 | |

4.19 | Overall Length (with/without the pedal raised) | l1 | mm | 2100/2562 | |

4.20 | Body Length (excluding forks) | l2 | mm | 950 | |

4.21 | Overall width | b1 | mm | 850 | |

4.22 | Fork dimensions | s/e/l | mm | 60/180/1150 | |

4.24 | Fork-carriage width | mm | 680 | ||

4.25 | Width over fork | b2 | mm | 570 | |

4.35 | Turning radius | Wa | mm | 1700 | |

Performance Data | 5.1 | Travel speed, with/without load | Km/h | 5.8/6 | |

5.2 | Lift speed, with/without load | mm/s | 90/110 | ||

5.3 | Lowering speed, with/without load | mm/s | 120/110 | ||

5.8 | Max. gradeability, with/without load | % | 6/15 | ||

5.10 | Service brake | Electromagnetic | |||

Electric Motor | 6.1 | Drive motor type | AC | ||

8.4 | Sound level at the driver’s ear | dB(A) | <70 |

Classification:

BYD Iron-Phosphate Technology

Battery 24V 130Ah

AC drive

AC control

Easy battery top-up solution

24V 30A on-board charger

3-hour charging time

5V USB port

Optional configuration:

1-hour fast-charging solution

Fork measurement on request

Metal mesh protection

Plexi-glass protection

Anti-slippering/reinforced wheel

Second-level Fully Articulated

Third-level Fully Articulated Mast

Customized Mast

Use:

Warehousing and Logistics industry, manufacturing industry, retail industry, electronics industry, food and beverage industry, pharmaceutical industry, agriculture

Product advantages:

Easy Maintenance: Utilizing CAN-BUS technological know-how for handy fault prognosis and troubleshooting, with a multifunctional instrument panel exhibiting battery level, hours of operation, fault maintenance, etc., for intuitive convenience.

Safe and Reliable: Equipped with security guardrails and shock-absorbing foot mats for higher driver protection. Also, elements such as overload safety and whole-vehicle electricity cutoff safety make sure worry-free operation.

Simple Operation: The multifunctional deal with presents limitless adjustment for a extra cozy and impenetrable operation, whilst the electric powered strength guidance gadget makes riding less difficult for the operator.

Versatility: Various mast specs are on hand to meet extraordinary working circumstance requirements.

Product inspection:

BYD forklift producer normally conducts rigorous product inspections and fine manage when producing forklift merchandise to make certain that their fantastic and overall performance meet excessive standards. These product inspects begins as from Raw Material Inspection: During the manufacturing process, BYD inspects the uncooked substances used. This consists of checking steel, digital components, lubricants, coatings, and more. Raw substances need to meet precise excellent requirements and specifications.

Manufacturing Process Inspection: During the forklift's manufacturing process, BYD video display units and inspects key system steps to make sure that every thing meets layout specifications. This consists of inspections of welding, mechanical processing, electrical connections, and different aspects.

Performance Testing: After the forklift is assembled, overall performance trying out is conducted. This consists of checking engine power, suspension systems, brake systems, driver manage systems, and extra to make certain that the forklift's overall performance meets special standards.

Safety Testing: BYD forklifts endure security trying out to make sure compliance with applicable security standards. This consists of collision tests, steadiness tests, electrical security tests, and others.

Quality Control: BYD implements a best manage system, such as inspection and checking out procedures, file records, worker training, and more, to make certain product consistency and quality.

Final Inspection: After the completion of forklift production, a last inspection is performed. This entails a complete test of the complete forklift to make certain that all elements are established correctly, there are no apparent defects, and overall performance is excellent.

Product Certification: Once the forklifts bypass all fundamental inspections and tests, they can also acquire applicable product certifications to show compliance with global and regional first-class and protection standards.

Packaging and transportation:

The packaging and transportation of forklifts are normally dealt with through the producer and suppliers to make certain that the merchandise are now not broken at some stage in transit.

Packaging: Forklifts are generally packaged earlier than leaving the manufacturing facility to shield their appearance and mechanical aspects from damage. Packaging normally consists of the use of wood crates, foam padding, plastic film, and strapping substances to make sure that the forklifts are now not affected via bumps and collisions all through transportation.

Inspection and Testing: Before leaving the factory, producers normally habits rigorous inspections and checking out on the forklifts to make certain that they feature excellent and can be safely transported. This consists of checking mechanical components, batteries, brake systems, and more.

Shipping: Once the forklifts are good packaged and omit inspection, they are organized for shipping. Forklifts can be transported to their vacation spot by avenue transportation, sea shipping, air freight, or different methods, relying on the distance, place and purchaser requirements.

Documentation and Permits: Depending on the necessities of the region, applicable files and approves can also want to be supplied to make certain that the forklifts can legally enter and be used in the region.

Company introduction:

BYD Forklift, hooked up in 2009, is a subsidiary of BYD Co., Ltd., placed in the Zhenjiang district of Shaoguan City. The complete funding for the assignment is 515 million RMB, masking an place of about 700,000 rectangular meters. It is basically accountable for producing BYD electric powered forklift series, such as the electric powered counterbalance forklift series, electric powered warehouse forklift series, and electric powered tow tractor series, amongst others.

BYD Forklift possesses a entire forklift manufacturing line, such as 4 machining and welding lines, one portray line, and three ultimate meeting lines, reaching an annual manufacturing ability of 30,000 units. Furthermore, the manufacturing unit has a expert trying out line and a complete first-class system, licensed underneath ISO9001, to make certain the fantastic of each forklift and grant clients with excellent exceptional and super service.

BYD Forklift has usually aimed to create a main international manufacturer in electric powered forklifts. 'Pursuing excellence and non-stop innovation' is the improvement philosophy of BYD Forklift, constantly optimizing and upgrading its products, protecting a ideal vary of functions from warehousing and logistics to port and terminal logistics. The market enlargement consists of more than one industries such as pharmaceuticals, food, bloodless chain processing, cosmetics, logistics, and more. In the procedure of market feedback, BYD electric powered forklifts have totally tested their tremendous blessings in inexperienced environmental safety and strength efficiency, receiving unanimous reward from clients at domestic and abroad, laying a strong basis for BYD electric powered forklifts to end up a globally relied on brand.

In response to market improvement needs, BYD Forklift is developing a complete electric powered forklift base in the Ningbo Industrial Park, integrating lookup and development, production, sales, and after-sales service. After completion, the mission will be founded in the Yangtze River Delta, overlaying East China and radiating nationwide and for export. The deliberate whole funding for BYD Forklift's Ningbo manufacturing unit is five hundred million RMB, which will encompass a 60,000 rectangular meters facility encompassing methods such as automobile machining, welding, painting, assembly, and modification, with the potential to produce 20,000 electric powered counterbalance forklifts and 30,000 warehouse forklifts annually.

Customer visit:

Before conducting client visits, the income or purchaser provider groups commonly time table appointments with clients and format the visit's timing, location, and agenda. This is achieved via telephone calls, emails, or different conversation methods. The sales or purchaser provider groups do specify the subjects to be mentioned with the customers, which consist of product presentations, problem resolution, training, commercial enterprise negotiations, or contract signings, amongst others. BYD’s consumer carrier groups commonly put together applicable archives and presentation substances to share with clients which might also encompass product manuals, presentation slides, samples, and more.

After the go to concludes, BYD’s income or consumer provider groups normally report the meeting's content, dialogue outcomes, and plans for the subsequent steps. We additionally preserve ongoing conversation with clients to make certain their wishes are met

FAQ:

1. Q: What industries are BYD pallet stacker forklifts appropriate for?

A: BYD pallet stacker forklifts are generally appropriate for a variety of industries, which includes warehousing and logistics, manufacturing, retail, electronics, meals and beverage, pharmaceuticals, and more. They are used for transporting, stacking, and storing goods, enhancing logistics effectivity and stock management.

2. Q: What are the exceptional fashions and capacities of BYD pallet stacker forklifts?

A: BYD affords a range of fashions and capacities for pallet stacker forklifts to meet the precise wants of specific customers. The preference of mannequin and capability relies upon on particular utility necessities and working environments.

3. Q: What kind of strength supply do BYD pallet stacker forklifts use?

A: BYD pallet stacker forklifts commonly use batteries as their strength source, which helps limit emissions, enhance strength efficiency, and minimize noise.

4. Q: Is running BYD pallet stacker forklifts effortless to learn?

A: Operating BYD pallet stacker forklifts is commonly fantastically handy to learn, however operators want to endure education and attain the applicable driver's license. BYD normally offers education and instructional substances to make sure that operators recognize secure operation and fine practices.

5. Q: Do BYD pallet stacker forklifts come geared up with security features?

A: Yes, BYD pallet stacker forklifts generally come outfitted with a number of security features, such as brake systems, reverse warning devices, seat belts, and emergency cease systems, to make sure the protection of operators and these around them.

6. Q: How do you operate the each day renovation of BYD pallet stacker forklifts?

A: Daily renovation is imperative for the overall performance and toughness of forklifts. BYD usually presents renovation tips and plans, together with duties such as normal inspections, section replacements, cleaning, and lubrication. Operators and upkeep personnel ought to observe these guidelines for forklift maintenance.

7. Q: Does BYD supply after-sales help and restore services?

A: Yes, BYD generally provides after-sales help and restore services, inclusive of coaching for renovation personnel, spare components supply, renovation and servicing plans, and technical support. If you come upon problems or require repairs, you can contact an licensed BYD carrier core or provider for assistance.

8. Q: What elective attachments and configurations are reachable for BYD pallet stacker forklifts?

A: BYD commonly gives a range of non-obligatory attachments and configurations to meet one-of-a-kind utility needs. These attachments and configurations can also consist of extraordinary sorts of forks, attachments, cabin configurations, hydraulic functions, and different customization alternatives to adapt to unique work environments and tasks.