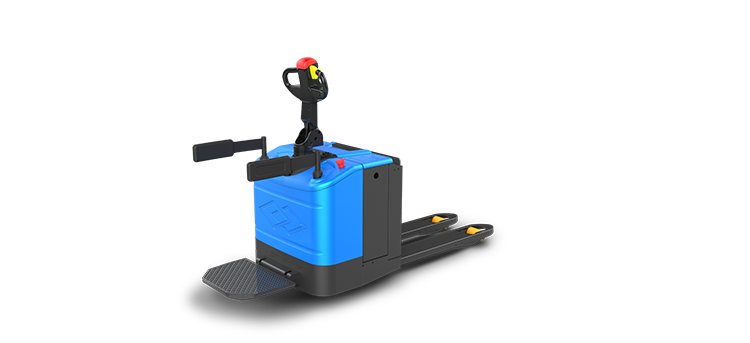

BYD Stand up Fork Truck PTP20S

Versatile Charging Options: This electric powered pallet provides bendy charging options with the desire between an wise quickly charging cupboard and an onboard charger. These preferences allow fast charging for delivered comfort on the go.

Steadfast and Stable Design: Built with a floating chassis and a parallel four-bar lifting system, this pallet ensures superior balance at some stage in operations, ensuing in smoother and greater constant fork lifting.

Smart Safety Features: Safety is paramount, and this pallet comprises clever protection measures. It consists of a whole-vehicle sleep function and computerized strength cut-off to prioritize protection and preserve energy, stopping battery over-discharge. Additionally, it comes with emergency braking, emergency reverse, and overload safety for heightened security and reliability.

Tailored Customization: This electric powered pallet gives personalized fork specs to accommodate a number of pallet coping with requirements. It additionally affords the comfort of USB ports and 5V/12V exterior energy provide options. Moreover, it points a flip-type guardrail mechanism that can be adjusted to various heights, improving its versatility.

Product description:

Allow me to introduce the two Ton BYD PTP20S electric powered pallet. This top notch BYD pallet mannequin is geared up with modern lithium iron phosphate battery science developed via BYD, making sure foremost protection and effectivity in its operation.

Product Parameter:

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | PTP20S | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Stand-on | |||

1.5 | Load capacity | Q | kg | 2000 | |

1.6 | Load center | C | mm | 600 | |

1.8 | Load distance, center of support arm wheel to face of fork | X | mm | 966 | |

1.9 | Wheelbase | Y | mm | 1311/1373 | |

Weight | 2.1 | Service weight including battery | kg | 650 | |

2.2 | Axle load, with load, front/rear | kg | 1150/1500 | ||

2.3 | Axle load, without load, front/rear | kg | 520/130 | ||

Wheels

| 3.1 | Wheel type | PU | ||

3.2 | Wheel size, front | mm | ∅230×75 | ||

3.3 | Wheel size, rear | mm | ∅85×110 | ||

3.4 | Additonal Wheels | mm | ∅100×50 | ||

3.5 | Wheels, number front rear (x=driven wheels) | 1x+2/4 | |||

3.6 | Track width, front | b10 | mm | 510 | |

3.7 | Track width, rear | b11 | mm | 370 | |

Dimensions | 4.4 | Lift height | h3 | mm | 120 |

4.9 | Height of tiller in drive position, min/max | h14 | mm | 970/1300 | |

4.15 | Lowered height | h13 | mm | 85 | |

4.19 | Overall length | l1 | mm | 1820/2290 | |

4.20 | Length to the face of forks | l2 | mm | 670 | |

4.21 | Overall width | b1 | mm | 720 | |

4.22 | Fork dimensions | s/e/l | mm | 55/180/1150 | |

4.25 | Width over fork | b2 | mm | 550 | |

4.32 | Ground clearance, center of wheelbase | m2 | mm | 30 | |

4.34 | Aisle width of pallets 800×1200 lengthways | Ast | mm | 2140 | |

4.35 | Turning radius | Wa | mm | 1680 | |

Performance Data | 5.1 | Travel speed, with/without load | Km/h | 9/12 | |

5.2 | Lift speed, with/without load | mm/s | 40/50 | ||

5.3 | Lowering speed, with/without load | mm/s | 50/40 | ||

5.8 | Max. gradeability, with/without load | % | 8/15 | ||

5.10 | Service brake | Electromagnetic | |||

Electric Motor | 6.1 | Drive motor rating S2 60 min. | kW | 1.9 | |

6.2 | Lift motor rating at S3 15% | kW | 1.2 | ||

6.4 | Battery voltage/nominal capacity K5 | V/Ah | 24/130 | ||

6.5 | Battery weight | kg | 70 | ||

8.4 | Sound level at the driver’s ear | dB(A) | 70 |

Classification:

Electric energy guidance to allow larger maneuverability for the operator and limit fatigue.

Shock-absorbent, non-slip platform affords operators a steady and satisfied position.

Pallet jack provides operators an ergonomic and adaptable design.

Automatic shutdown when deal with is launched or positioned in a vertical / horizontal position.

Optimal place of the emergency give up button to make it safer.

Optional configuration:

1-hour fast-charging solution

Charger 24V 100A

30A Onboard Charger

Fork measurement on request

Tandem load wheel

Cold keep preparation

1465mm load backrest

130Ah Lithium Iron Phosphate (LiFePO4) Battery

270Ah Lithium Iron Phosphate (LiFePO4) Battery

Standard Tires

Non-slip Tires

Single-bearing

Wheels / Double-bearing Wheels

Use:

Warehousing and Logistics industry, manufacturing industry, retail industry, electronics industry, meals and beverage industry, pharmaceutical industry, agriculture.

Product advantages:

Versatile Charging Options: This electric powered pallet provides bendy charging solutions with the preference between an clever quick charging cupboard and an onboard charger. These selections allow speedy charging for brought comfort on the go.

Steadfast and Stable Design: Built with a floating chassis and a parallel four-bar lifting system, this pallet ensures greater balance in the course of operations, ensuing in smoother and extra regular fork lifting.

Smart Safety Features: Safety is paramount, and this pallet contains clever security measures. It consists of a whole-vehicle sleep feature and computerized electricity cut-off to prioritize security and preserve energy, stopping battery over-discharge. Additionally, it comes with emergency braking, emergency reverse, and overload safety for heightened security and reliability.

Tailored Customization: This electric pallet affords personalized fork specs to accommodate more than a few pallet managing requirements. It additionally presents the comfort of USB ports and 5V/12V exterior strength provide options. Moreover, it points a flip-type guardrail mechanism that can be adjusted to various heights, improving its versatility.

Product inspection:

BYD Forklift, as a respectable forklift manufacturer, locations magnificent emphasis on conducting rigorous product inspections and imposing strong satisfactory manipulate measures to uphold the excessive requirements of excellent and overall performance related with their forklift products. This meticulous first-class assurance technique commences with Raw Material Inspection, the place BYD scrupulously assesses the uncooked substances utilized in production, such as steel, digital components, lubricants, coatings, and different indispensable elements. The uncooked substances have to strictly adhere to unique pleasant requirements and specifications.

Furthermore, in the course of the Manufacturing Process, BYD vigilantly oversees and inspects imperative manufacturing levels to make sure that every element aligns with the distinctive sketch specifications. This entails meticulous scrutiny of welding, mechanical processing, electrical connections, and a range of different sides of the manufacturing process.

Following the meeting of the forklift, BYD conducts complete Performance Testing to consider a number parameters, which includes engine power, suspension systems, brake systems, driver manipulate systems, and more. These assessments are performed to make sure that the forklift's overall performance complies with the predefined requirements of excellence.

Safety stays a paramount concern, prompting BYD to challenge its forklifts to rigorous Safety Testing, which encompasses necessary opinions such as collision tests, balance assessments, electrical protection tests, and an array of different safety-related examinations to exceed the stipulated security standards.

To make sure consistency and excellence in their products, BYD has applied a complete Quality Control system, integrating meticulous inspection and trying out protocols, unique documentation practices, worker training, and different quintessential measures.

Subsequently, a Final Inspection is carried out upon the completion of forklift production, entailing a complete examination of the complete forklift to affirm specific element installation, the absence of obvious defects, and the attainment of most excellent performance.

Upon correctly passing all requisite inspections and tests, the forklifts might also gain applicable product certifications, serving as a testomony to their strict adherence to global and regional best and security standards.

Packaging and transportation:

Manufacturers and suppliers generally take on the duty of packaging and transporting forklifts to protect these merchandise from workable harm throughout transit.

Packaging: To maintain the look and mechanical integrity of forklifts, they are mechanically encased in protecting packaging earlier than departing the factory. This packaging routine regularly includes the use of wood crates, foam padding, plastic film, and strong strapping materials. These measures are taken to make certain that the forklifts stay unscathed and unaffected with the aid of any bumps or collisions that may also take place in the course of transportation.

Inspection and Testing: Prior to leaving the factory, producers usually difficulty forklifts to stringent inspections and checking out procedures. These measures are in region to make certain that the forklifts are in most advantageous working circumstance and secure for transportation. Comprehensive examinations are conducted, protecting mechanical components, batteries, brake systems, and quite a number different integral elements.

Shipping: Once the forklifts are accurately packaged and have effectively handed inspection, they are made prepared for shipping. The desire of transportation technique for the forklifts relies upon on a variety of factors, inclusive of distance, destination, regional considerations, and purchaser preferences. Options can also encompass street transportation, sea shipping, air freight, or different appropriate capability to facilitate well timed and impervious delivery.

Documentation and Permits: Depending on the precise necessities imposed through the vacation spot united states of america or region, it may additionally be integral to furnish pertinent files and permits. These measures make certain that the forklifts can be legally imported and operated inside the unique area, for that reason adhering to all relevant rules and facilitating a clean and lawful transportation process.

Company introduction:

Established in 2009, BYD Forklift operates as a subsidiary of BYD Co., Ltd., and it is strategically placed in the Zhenjiang district of Shaoguan City. This spectacular pastime has viewed a sizable complete funding of 515 million RMB, overlaying an expansive location spanning about 700,000 rectangular meters. The core accountability of BYD Forklift lies in the manufacturing of a various vary of BYD electric powered forklift series. This consists of the electric powered counterbalance forklift series, electric warehouse forklift series, and electric powered tow tractor series, amongst different brilliant offerings.

BYD Forklift has diligently hooked up a complete forklift manufacturing line, comprising 4 devoted machining and welding lines, in addition to a well-equipped portray line and three ultimate meeting lines. This infrastructure empowers the facility with an amazing annual manufacturing capacity, succesful of turning in 30,000 devices to meet market demand. Furthermore, BYD Forklift locations a sturdy emphasis on great assurance, bolstered through a expert checking out line and a complete first-rate machine that has earned ISO9001 certification. These stringent measures are meticulously carried out to make certain the unwavering fine of every forklift, thereby promising clients a persistently excessive stage of excellent and high-quality service.

As phase of its enduring dedication to excellence, BYD Forklift has persistently aspired to emerge as a preeminent international company in the realm of electric powered forklifts. The company's unwavering improvement philosophy is encapsulated in the concepts of "Pursuing excellence and non-stop innovation." This ethos drives BYD Forklift to continuously refine and beautify its product portfolio, supplying options that cater to a broad spectrum of applications, ranging from warehousing and logistics to port and terminal logistics. This strategic growth extends its impact throughout various industries, encompassing pharmaceuticals, food, bloodless chain processing, cosmetics, and a number of segments inside the logistics domain. In response to market feedback, BYD electric powered forklifts have persistently showcased their super benefits in inexperienced environmental safety and power efficiency. These attributes have garnered regularly occurring acclaim from each home and global clientele, setting up a sturdy basis for BYD electric powered forklifts to evolve into a globally relied on brand.

In alignment with the dynamic wants of the market, BYD Forklift has embarked on the development of a complete electric powered forklift base located inside the Ningbo Industrial Park. This forward-looking initiative seamlessly integrates lookup and development, production, sales, and after-sales provider to successfully tackle market demands. Upon profitable completion, this task will serve as a pivotal hub inside the Yangtze River Delta region, strategically placed to cowl East China whilst radiating its impact nationwide and globally for export purposes. The formidable project is underpinned by means of a deliberate whole funding of five hundred million RMB, facilitating the introduction of a sprawling facility spanning 60,000 rectangular meters. Within this facility, critical techniques such as automobile machining, welding, painting, assembly, and change will take place, aiding a enormous annual production capacity. The facility is poised to supply 20,000 electric powered counterbalance forklifts and 30,000 warehouse forklifts annually, similarly cementing BYD Forklift's role as a chief in the industry.

Customer visit:

Prior to embarking on purchaser visits, BYD's income and consumer carrier groups diligently organize appointments with clients, taking care to meticulously design the visit's schedule, location, and agenda. These preparations are efficaciously coordinated via a range of conversation channels, encompassing telephone conversations, e-mail correspondences, and different appropriate ability of contact. As an fundamental section of this preparatory process, the income and patron provider groups explicitly define the unique topics that will be addressed at some stage in these engagements. These subjects embody a various array of subjects, ranging from complete product shows and high quality problem decision techniques to specialised education sessions, elaborate commercial enterprise negotiations, and the formal signing of contracts, amongst different imperative matters. To beautify the general client experience, BYD's consumer provider groups additionally devote their efforts to compiling pertinent archives and presentation materials. These substances may additionally consist of targeted product manuals, informative presentation slides, tangible product samples, and a plethora of extra sources designed to enrich the client's grasp and grasp of BYD's offerings.

Following the profitable conclusion of the purchaser visit, BYD's adept income and purchaser provider groups embark on a meticulous documentation process. This method comprehensively encompasses the recording of all dialogue points, the consequences of these dialogues, and the strategic plans that have been formulated for the subsequent phases of the patron relationship. Going past the preliminary meeting, BYD stays dedicated to retaining an ongoing and open line of verbal exchange with its clients. This enduring verbal exchange framework ensures that the evolving wants and necessities of clients are constantly addressed, therefore facilitating the provision of top-tier carrier and support.

FAQ:

1. Q: What industries are BYD pallet coping with forklifts appropriate for?

A: BYD pallet managing forklifts are commonly appropriate for quite a number industries, together with warehousing and logistics, manufacturing, retail, electronics, meals and beverage, pharmaceuticals, and more. They are used for transporting and stacking goods, enhancing logistics efficiency.

2. Q: What are the one-of-a-kind fashions and capacities of BYD pallet dealing with forklifts?

A: BYD provides a vary of fashions and capacities for pallet managing forklifts to meet the unique wishes of one-of-a-kind customers. The preference of mannequin and ability relies upon on your specific software necessities and working environment.

3. Q: What electricity supply do these forklifts use?

A: BYD pallet managing forklifts commonly use batteries as their strength source. This is completed to limit emissions, enhance power efficiency, and minimize noise.

4. Q: Is working BYD pallet dealing with forklifts convenient to learn?

A: Operating BYD pallet coping with forklifts is commonly quite convenient to learn, however operators want to bear education and achieve the applicable driver's license. BYD normally gives education and instructional substances to make sure that operators recognize protected operation and fine practices.

5. Q: Do these forklifts have security features?

A: Yes, BYD pallet coping with forklifts normally come outfitted with a variety of protection features, which include brake systems, reverse warning devices, seat belts, and emergency braking systems, to make sure the security of operators and these round them.

6. Q: How do you keep and provider BYD pallet coping with forklifts?

A: Maintenance and servicing are indispensable for the overall performance and sturdiness of forklifts. BYD usually presents renovation and servicing guidelines and plans, masking duties such as everyday inspections, phase replacements, cleaning, and lubrication. Operators and preservation personnel have to observe these tips for protection and servicing.

7. Q: Does BYD provide after-sales aid and restore services?

A: Yes, BYD usually gives after-sales assist and restore services, such as coaching for protection personnel, spare components supply, upkeep and servicing plans, and technical support. If you come upon troubles or require repairs, you can contact an licensed BYD provider core or provider for assistance.

8. Q: What non-compulsory attachments and configurations are accessible for these forklifts?

A: BYD normally provides a range of non-obligatory attachments and configurations to meet extraordinary utility needs. These might also encompass a number kinds of forks, attachments, unique seat and cabin configurations, and different customization options.